The Problem with Traditional Solvents

In industries like electronics, aerospace, and medical device manufacturing, precision cleaning is critical. For decades, companies relied on solvents like HCFCs (e.g., HCFC-141b) and PFCs (Perfluorocarbons) for degreasing, flux removal, and component cleaning. However, these chemicals come with severe drawbacks:

Ozone depletion (HCFCs have high ODP – Ozone Depletion Potential).

High Global Warming Potential (GWP) – Some PFCs have GWPs thousands of times worse than CO₂.

Toxicity & flammability risks – Many traditional solvents require strict handling procedures.

With tightening environmental regulations (e.g., Montreal Protocol, EU F-Gas Regulations), manufacturers urgently need safer, sustainable alternatives-without compromising performance.

Introducing HFE-347: The Future of Precision Cleaning

HFE 347 (1,1,2,2-Tetrafluoroethyl 2,2,2-trifluoroethyl ether) is a high-performance Hydrofluoroether(HFE) Fluorine cleaning solvent engineered for precision cleaning across multiple industries. Its unique properties-rapid evaporation, zero residue, and material safety-make it ideal for applications where traditional solvents fall short.

Key Advantages of HFE347:

✅ Zero Ozone Depletion (ODP = 0) – Fully compliant with global environmental standards.

✅ Low GWP – Significantly lower climate impact than PFCs or HFCs.

✅ Non-flammable & Chemically Stable – Safe for use in sensitive environments (e.g., cleanrooms).

✅ Fast-Evaporating, No Residue – Ideal for high-precision applications like semiconductor cleaning.

✅ Material Compatibility – Safe on plastics, metals, and elastomers without corrosion.

Where Is HFE-347 Used? Industry Applications of This Advanced Fluorinated Cleaning Solvent

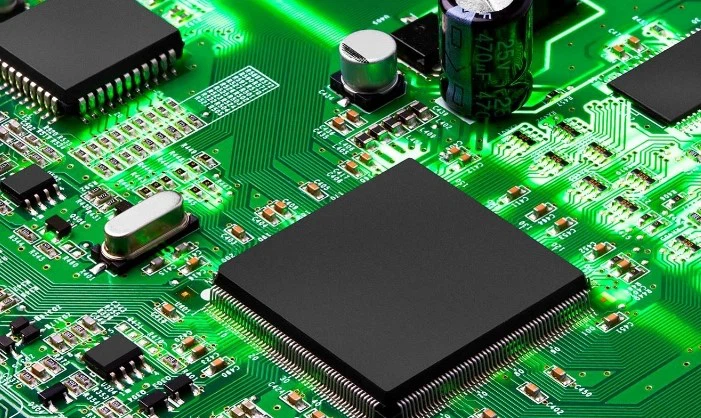

1. Electronics Manufacturing & PCB Cleaning

Superior Electric Parts Cleaner for Sensitive Components

HFE 347 is widely used as an electrical cleaning solvent in:

✔ PCB (Printed Circuit Board) Cleaning – Effectively removes solder flux residues (no-clean flux, rosin-based flux) without damaging delicate circuitry.

✔ Semiconductor & Microelectronics – Cleans wafer substrates, connectors, and relays without leaving ionic contaminants.

✔ Replacing 3M Novec 7100 – Many manufacturers now use HFE-347 as a drop-in alternative .

2. Solder Flux Removal & Post-Assembly Cleaning

The Ultimate Solder Flux Remover for High-Throughput Production

HFE-347 excels in post-soldering cleaning, where traditional solvents struggle:

✔ No-Clean Flux Remover – While "no-clean" fluxes claim to leave harmless residues, HFE-347 ensures complete removal for critical applications (e.g., aerospace, medical devices).

✔ Selective Cleaning – Can be used in batch cleaning, spray systems, or ultrasonic tanks without degrading conformal coatings.

3. Medical Device & Optical Component Cleaning

A Safe, Non-Toxic Solvent for Critical Applications

HFE-347 is trusted in medical and optical industries because:

✔ No residue – Critical for endoscopes, surgical tools, and laser lenses.

✔ Material-safe – Won't damage plastics, elastomers, or coated optics.

✔ Meets ISO 10993 biocompatibility standards – Unlike chlorinated solvents.

✅ Example Use Case:

Cleaning fiber-optic connectors – HFE-347 removes oils and particles without streaking.

4. Aerospace & Defense: Replacing Banned Solvents

A High-Performance Alternative to HCFCs & PFCs

Aerospace manufacturers are switching to HFE-347 for:

✔ Avionics Cleaning – Removes contaminants from circuit boards without corrosion risks.

✔ Fuel System Maintenance – Safe for O-rings and composite materials.

✔ Replacing Banned Solvents – Such as HCFC-141b and 3M Novec flux remover 7100 (due to regulatory phase-outs).

✅ Why Aerospace Chooses HFE-347:

Non-flammable (unlike acetone) – Reduces fire hazards in confined spaces.

Compatible with MIL-STD cleaning standards.

5. Industrial Degreasing & Precision Metal Cleaning

A Versatile Fluorinated Solvent for Heavy-Duty Applications

HFE-347 is also used in:

✔ Metal Parts Degreasing – Removes cutting oils, lubricants, and metal shavings without affecting tolerances.

✔ 3D Printing & Additive Manufacturing – Cleans resin and support material from intricate parts.

✅ Advantages Over Hydrocarbon Solvents:

No VOC emissions – Complies with strict air quality regulations.

Recyclable in closed-loop systems – Lowers long-term costs.

Conclusion: HFE 347 – The Future of Industrial Cleaning

Whether you need an:

Electric parts cleaner for PCBs,

Solder flux remover for no-clean residues,

3M Novec 7100 replacement with better performance,

Non-toxic solvent for medical devices,

HFE-347 delivers unmatched safety, efficiency, and compliance.

Contact us today for a free sample or technical consultation!

Our address

Room 1102, Unit C, Xinjing Center, No.25 Jiahe Road, Siming District, Xiamen, Fujan, China

Phone Number

+86-592-5803997

susan@xmjuda.com